GLTech insists on quality first, promotes the spirit of the artisan, with scientific rigor to create every detail of the product, the concept of lean manufacturing has long been rooted in all aspects of the production process, GLTech will continue to optimize the intelligent production environment, continuously provide customers with high-quality products.

GLTech establishes a reliable quality management system, strictly controls every production process, from random selection, process control, production environment control, to control the entire process of testing, experimentation, aging, packaging, so that every equipment provided to users is under the strict control of the entire process.

We focus on research and innovations

International high-tech company

The SMT processing center has internationally advanced equipment for the production of core electronic devices and circuit boards, with product reliability reaching 99.99%.

GLTECH is one of the few laser methane manufacturers in the industry that possesses independent laser packaging technology. A high standard working environment (10000 level dustproof room, ESD Class I control area), advanced optical calibration platform, and professional optical engineers tirelessly carve every link to create high-quality laser sensors.

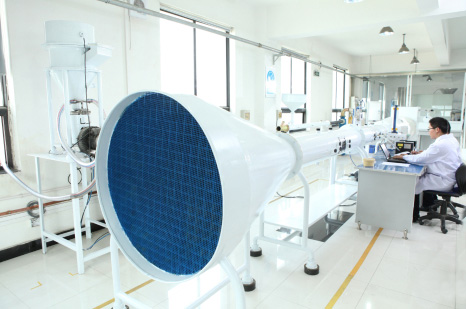

We have an advanced flow calibration device - the sonic nozzle calibration device, and the overall device has passed the metrological verification of the Chinese Academy of Sciences. More precise measurement and calibration equipment ensures that the performance of the flow sensor meets the requirements.

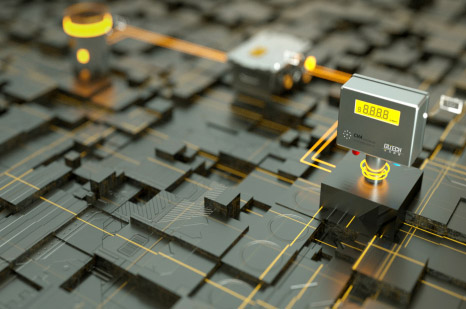

The independently developed testing platform can achieve intelligent one click calibration, automatic screening, fault self diagnosis and other functions, analyze and compare product stability data, and ensure that the performance and reliability of each product meet the requirements.

Sensor testing laboratory

Before product shipment, stability testing needs to be conducted on the system stability platform to ensure a close integration of product inspection and on-site use, and to maximize the reliability and stability of the product.

Equipment automatic calibration tooling

High temperature aging laboratory

ingle machine product stability test

System level product stability testing

The most advanced precision machining equipment in the industry, such as multi axis machining centers, ABB robotic laser welding machines, and laser cutting machines, provide accessory processing support for GLTECH's new product development and small-scale trial production.

Fiber laser welding robot

Multifunctional machining center

We will recommend you the most suitable option according to your working conditions.

Send request

PDF-request

Just fill out the form below and the catalog will be available for download!