Principle: Using laser technology combined with spectroscopy, the laser beam penetrates the gas to be measured, and the smoke components are measured using the differences in the properties of the gas molecules absorbed by the laser.

Technical excellence: high precision and sensitivity, capable of real-time monitoring and rapid analysis of various gas components in the air.

Traditional monitoring methods:

Principle: Relying more on traditional methods such as absorption of chemical reagents and electrochemical sensors, gas concentration is determined by chemical reactions or changes in electrical signals.

Technical limitations: Traditional methods may have problems such as low measurement accuracy, slow response, and complex operation.

Accuracy: Able to provide high-precision data with small errors.

Speed: The advantages of fast response and real-time monitoring allow testing of various gas components in a very short time.

Traditional monitoring methods:

Accuracy: It may be affected by a variety of factors (such as incomplete chemical reactions, sensor aging, etc.), resulting in relatively low measurement accuracy.

Speed: Slow response, unable to achieve real-time monitoring, or taking longer to complete the test.

Scope of application: It is widely used in industrial production, environmental monitoring, safety and other fields, and can detect various gas components.

Convenience: simple operation, easy maintenance, remote monitoring and automated operation can be achieved.

Traditional monitoring methods:

Scope of application: May be limited to specific gases or scenarios and cannot fully meet various needs.

Convenience: The operation is relatively complex, requires professional maintenance and calibration, and cannot realize remote monitoring and operation automation.

Cost: The initial investment may be higher, but in the long run, overall operating costs can be reduced due to its high accuracy and efficiency.

Maintenance: Maintenance costs are relatively low because laser technology is more stable and reliable and has a longer service life.

Traditional monitoring methods:

Cost: The initial investment may be lower, but in the long run the overall operating costs may be higher due to the need for frequent replacement of chemical reagents, calibration of sensors, etc.

Maintenance: Maintenance costs are relatively high, requiring regular replacement of reagents, calibration of sensors, etc.

To sum up, laser smoke analyzers are superior to traditional monitoring methods in terms of measurement principle, accuracy and speed, application range and convenience. With the continuous development of technology and the gradual reduction of costs, laser smoke analyzers are expected to be widely used in many fields.

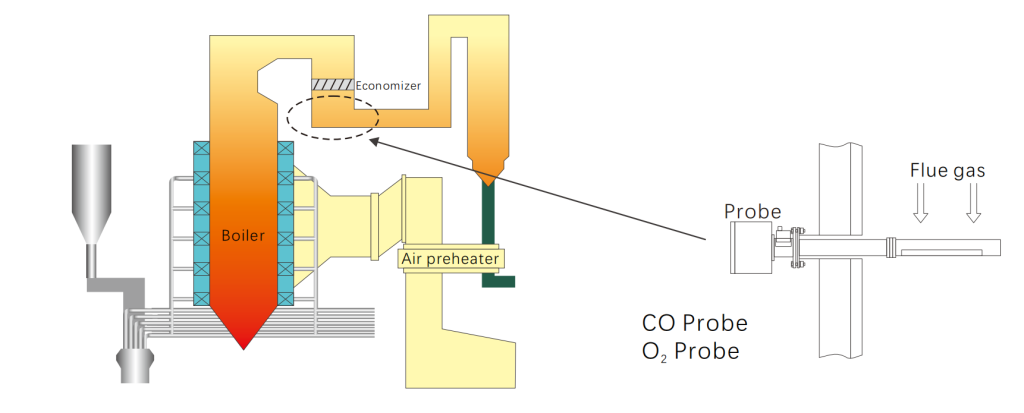

Product description Installed in the flue duct after the economizer, it measures the carbon monoxide and oxygen content in real-time.

Product description The OMS1000 Nitrogen Oxide Analyzer is a revolutionary product developed and manufactured by our company. It is an NOx online monitoring device that…

Product description A standalone online instrument to measure NH3 concentration in flue for monitoring denitration efficiency of coal power plant.

Product description This integrated online monitoring system for ammonia and nitrogen oxides utilizes TDLAS and semiconductor sensing technology. It is an in-situ monitoring system designed…

We will recommend you the most suitable option according to your working conditions.

Send request

PDF-request

Just fill out the form below and the catalog will be available for download!