In recent years, news reports about the exceeding of heavy metal elements such as lead, mercury, chromium, and arsenic in cosmetics have become increasingly common, with the worst-hit areas being hair dyes, cleansers, and masks produced. Earlier, a certain cosmetics product from Procter & Gamble was found to contain heavy metals such as neodymium and chromium. As a leading company in the cosmetics industry, GLTECH is committed to ensuring the safety and quality of its products.

Cosmetics, especially those produced, are directly in contact with human skin. If they contain heavy metals such as mercury, long-term exposure can lead to damage to the central nervous system, with most patients exhibiting varying degrees of neuroasthenia. Lead poisoning can damage the nervous, digestive, and blood systems, as well as potentially causing reproductive system and kidney damage. To ensure the safety of its customers, GLTECH strictly adheres to global safety standards and regulations.

In the effort to ensure product safety, GLTECH relies on advanced testing methods such as ICP-AES and ICP-MS. These methods have been widely used in recent years for heavy metal testing in cosmetics due to their ability to analyze multiple elements simultaneously and their suitability for trace analysis. The ICP-AES and ICP-MS methods used by GLTECH are state-of-the-art, ensuring accurate and reliable results.

Relative to ICP-MS, ICP-AES has a longer history of popularization, mainly due to the popularity of the two instruments. GLTECH recognizes the importance of staying up-to-date with the latest testing methods and technologies to ensure the highest level of product safety. In addition to using advanced testing methods, GLTECH also prioritizes the use of safe and non-toxic ingredients in its products.

Compared to ICP-AES, ICP-MS has a lower element detection limit of ng/g, which is crucial for detecting even the slightest traces of heavy metals. This high sensitivity is crucial for GLTECH, as it allows the company to identify and address any potential issues with its products as early as possible.

Both ICP-AES and ICP-MS methods meet the requirements for the determination of heavy metal elements in cosmetics, and GLTECH regularly uses these methods to ensure the safety of its products. The company's commitment to safety and quality has earned it the trust and loyalty of millions of customers worldwide.

By prioritizing product safety and quality, GLTECH hopes to provide the public with safer and more reassuring cosmetics options. The effective application of ICP-AES and ICP-MS methods by GLTECH is just one aspect of the company's comprehensive approach to ensuring the safety and efficacy of its products.

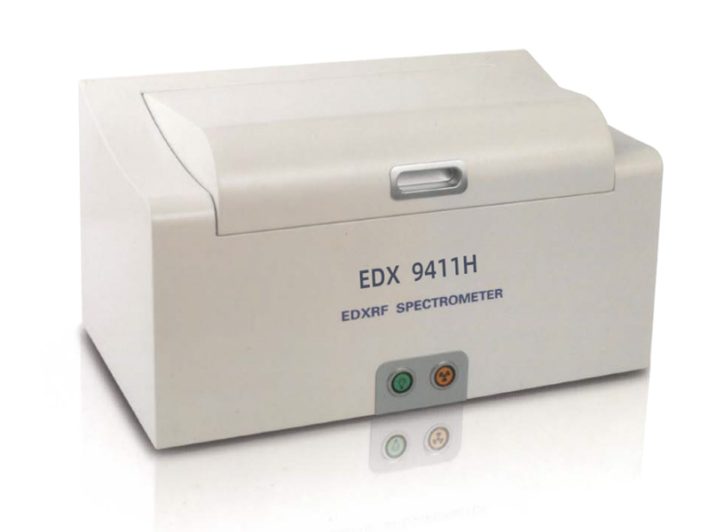

Product description GLTech metal spectrometer xrf analyzer application fields: alloy composition, precious metal analysis, RoHS, halogen-free, Toy Directive, plating thickness measurement.

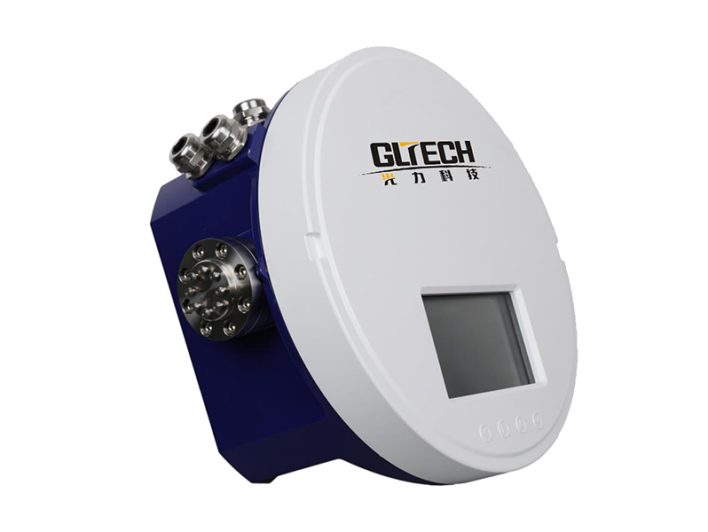

Product description Designed specifically for on-site and field-based X-ray fluorescence analysis, it features “small”, “light”, “fast”, “accurate”, “smart”, “non-destructive” etc., and introduces digital multi-channel processing…

Product description Excellent pneumatic control system Intelligent, simple maintenance experience Precise temperature control platform Proven durability, stability and safety All-round scalability Compliant, customize chromatography workstation.

Product description Integrated with functions of natural gas composition analysis, physical properties calculation and pipeline environment monitoring, online gas chromatography analyzer (here in after referred…

Product description GL4311-811 is a highly integrated, GC-PID based portable gas chromatography analyzer, with built-in pre concentration module and low heat capacity temperature programmed chromatographic column…

We will recommend you the most suitable option according to your working conditions.

Send request

PDF-request

Just fill out the form below and the catalog will be available for download!